Market Policies for Wire-Winding Resistors

I. Introduction

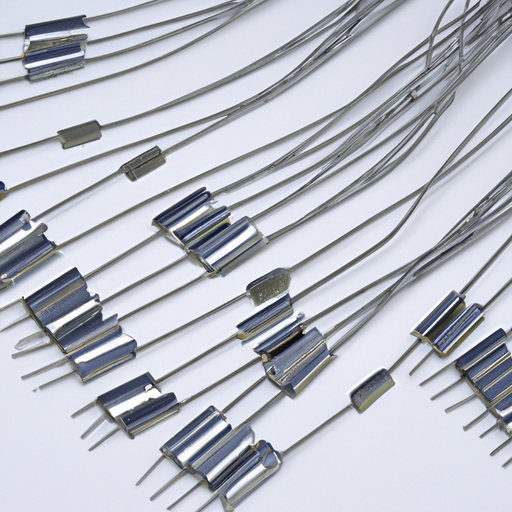

Wire-winding resistors are essential components in various electronic applications, providing resistance in circuits to control current flow. These resistors are known for their high precision, stability, and ability to handle high power levels, making them indispensable in industries such as automotive, aerospace, telecommunications, and industrial automation. As the demand for reliable and efficient electronic components continues to grow, understanding the market policies that govern wire-winding resistors becomes crucial for manufacturers, suppliers, and consumers alike.

This blog post will explore the market policies affecting wire-winding resistors, including market dynamics, regulatory frameworks, pricing strategies, trade policies, environmental considerations, and technological advancements. By examining these factors, we can gain insights into the current landscape and future prospects of the wire-winding resistor market.

II. Market Overview

A. Global Demand for Wire-Winding Resistors

The global demand for wire-winding resistors has been steadily increasing, driven by the expansion of key industries. The automotive sector, for instance, relies heavily on these resistors for various applications, including electric vehicles (EVs) and advanced driver-assistance systems (ADAS). Similarly, the telecommunications industry utilizes wire-winding resistors in network infrastructure and communication devices.

1. Key Industries Utilizing Wire-Winding Resistors

Automotive: With the rise of electric and hybrid vehicles, the demand for high-performance resistors has surged.

Aerospace: Wire-winding resistors are critical in avionics and control systems, where reliability is paramount.

Industrial Automation: As factories become more automated, the need for precise control systems has increased the demand for wire-winding resistors.

2. Trends in Demand and Supply

The market has witnessed a shift towards high-performance and miniaturized components, leading to innovations in wire-winding resistor design. However, supply chain disruptions, particularly during the COVID-19 pandemic, have posed challenges in meeting the growing demand.

B. Major Manufacturers and Suppliers

The wire-winding resistor market is characterized by a mix of established players and emerging companies. Leading manufacturers include Vishay Intertechnology, Ohmite Manufacturing Company, and TE Connectivity, among others. These companies dominate the market due to their extensive product portfolios, technological expertise, and strong distribution networks.

1. Leading Companies in the Wire-Winding Resistor Market

Vishay Intertechnology: Known for its wide range of resistors, including wire-wound types, Vishay is a key player in the market.

Ohmite Manufacturing Company: Specializes in high-power resistors and has a strong presence in the industrial sector.

TE Connectivity: Offers a variety of electronic components, including wire-winding resistors, catering to multiple industries.

2. Market Share Analysis

Market share analysis reveals that a few key players hold significant portions of the market, but there is also room for smaller companies to innovate and capture niche segments.

III. Regulatory Framework

A. International Standards and Certifications

The wire-winding resistor market is subject to various international standards and certifications that ensure product quality and safety.

1. IEC (International Electrotechnical Commission) Standards

The IEC sets global standards for electrical and electronic components, including resistors. Compliance with these standards is essential for manufacturers to ensure their products meet safety and performance criteria.

2. RoHS (Restriction of Hazardous Substances) Compliance

RoHS compliance is crucial for manufacturers targeting markets in the European Union. This regulation restricts the use of hazardous substances in electronic products, pushing manufacturers to adopt safer materials and processes.

B. National Regulations

Different countries have their own regulations that impact the manufacturing and distribution of wire-winding resistors.

1. Overview of Regulations in Key Markets

USA: The Federal Communications Commission (FCC) regulates electronic components to ensure they do not interfere with communication systems.

EU: In addition to RoHS, the EU has regulations regarding waste electrical and electronic equipment (WEEE) that affect product lifecycle management.

Asia: Countries like China and Japan have their own sets of regulations that manufacturers must navigate to access these markets.

2. Impact of Regulations on Manufacturing and Distribution

Compliance with these regulations can increase manufacturing costs but is essential for market access. Manufacturers must invest in quality control and certification processes to meet these standards.

IV. Pricing Policies

A. Factors Influencing Pricing of Wire-Winding Resistors

Several factors influence the pricing of wire-winding resistors, including material costs, manufacturing processes, and market competition.

1. Material Costs

The cost of raw materials, such as copper and resistive wire, significantly impacts the pricing of wire-winding resistors. Fluctuations in commodity prices can lead to changes in product pricing.

2. Manufacturing Processes

The complexity of manufacturing processes, including winding techniques and quality control measures, also affects pricing. Advanced manufacturing technologies may lead to higher initial costs but can result in better performance and reliability.

3. Competition and Market Dynamics

The competitive landscape plays a crucial role in pricing strategies. Manufacturers must balance cost recovery with competitive pricing to attract customers.

B. Pricing Strategies Employed by Manufacturers

Manufacturers employ various pricing strategies to position their products in the market.

1. Cost-Plus Pricing

This strategy involves calculating the total cost of production and adding a markup to determine the selling price. It ensures that manufacturers cover their costs while making a profit.

2. Value-Based Pricing

Value-based pricing focuses on the perceived value of the product to the customer. Manufacturers may charge a premium for high-performance resistors that offer superior reliability and efficiency.

3. Competitive Pricing

In a competitive market, manufacturers may adopt competitive pricing strategies to attract customers, often leading to price wars that can impact profitability.

V. Trade Policies

A. Import and Export Regulations

Trade policies significantly influence the wire-winding resistor market, particularly regarding import and export regulations.

1. Tariffs and Duties on Wire-Winding Resistors

Tariffs imposed on imported components can increase costs for manufacturers and consumers. Understanding these tariffs is essential for companies operating in multiple regions.

2. Trade Agreements Affecting the Market

Trade agreements, such as the USMCA (United States-Mexico-Canada Agreement), can facilitate smoother trade between countries, impacting pricing and availability.

B. Impact of Trade Policies on Global Supply Chains

1. Challenges Faced by Manufacturers

Trade policies can create challenges, such as increased costs and delays in supply chains. Manufacturers must navigate these complexities to maintain competitiveness.

2. Opportunities for Market Expansion

Conversely, favorable trade agreements can open new markets for manufacturers, providing opportunities for growth and expansion.

VI. Environmental Policies

A. Sustainability Initiatives in the Wire-Winding Resistor Industry

The wire-winding resistor industry is increasingly focusing on sustainability initiatives to meet consumer demand for eco-friendly products.

1. Eco-Friendly Materials and Manufacturing Processes

Manufacturers are exploring the use of sustainable materials and processes to reduce their environmental impact. This includes sourcing materials responsibly and adopting energy-efficient manufacturing techniques.

2. Waste Management and Recycling Practices

Implementing effective waste management and recycling practices is becoming a priority for manufacturers, aligning with global sustainability goals.

B. Impact of Environmental Regulations on Market Practices

1. Compliance Costs

Adhering to environmental regulations can lead to increased compliance costs for manufacturers. However, these investments can enhance brand reputation and customer loyalty.

2. Consumer Demand for Sustainable Products

As consumers become more environmentally conscious, the demand for sustainable products is rising. Manufacturers that prioritize sustainability may gain a competitive edge in the market.

VII. Technological Advancements

A. Innovations in Wire-Winding Resistor Design and Manufacturing

Technological advancements are driving innovation in wire-winding resistor design and manufacturing processes.

1. Automation and Smart Manufacturing

The adoption of automation and smart manufacturing technologies is improving efficiency and precision in resistor production, leading to higher quality products.

2. Advances in Materials Science

Innovations in materials science are enabling the development of new resistor types with enhanced performance characteristics, such as higher power ratings and improved thermal stability.

B. Influence of Technology on Market Policies

1. Adaptation to New Technologies

Manufacturers must adapt to new technologies to remain competitive. This includes investing in research and development to stay ahead of market trends.

2. Regulatory Responses to Technological Changes

As technology evolves, regulatory bodies may update standards and regulations to address new challenges and ensure product safety.

VIII. Market Challenges and Opportunities

A. Challenges Faced by Manufacturers

Manufacturers in the wire-winding resistor market face several challenges, including:

1. Supply Chain Disruptions

Global supply chain disruptions, exacerbated by the COVID-19 pandemic, have impacted the availability of raw materials and components.

2. Competition from Alternative Resistor Technologies

The rise of alternative resistor technologies, such as thick film and thin film resistors, poses a challenge to traditional wire-winding resistors.

B. Opportunities for Growth

Despite these challenges, there are significant opportunities for growth in the wire-winding resistor market.

1. Emerging Markets

Emerging markets, particularly in Asia and Africa, present opportunities for manufacturers to expand their customer base and increase sales.

2. Increasing Demand for High-Performance Resistors

The growing demand for high-performance resistors in advanced applications, such as renewable energy and electric vehicles, offers manufacturers a chance to innovate and capture new market segments.

IX. Conclusion

In conclusion, the market policies affecting wire-winding resistors are multifaceted, encompassing regulatory frameworks, pricing strategies, trade policies, environmental considerations, and technological advancements. As the demand for reliable and efficient electronic components continues to rise, manufacturers must navigate these policies to ensure sustained growth and competitiveness.

The future outlook for the wire-winding resistor market appears promising, with opportunities for innovation and expansion in emerging markets. By adapting to changing market policies and consumer preferences, manufacturers can position themselves for success in this dynamic industry.

X. References

A comprehensive list of academic papers, industry reports, and regulatory documents would be included here to support the research and insights presented in this blog post.