How Should Spot Resistor Manufacturers Choose?

I. Introduction

In the world of electronics, resistors play a crucial role in controlling current flow and ensuring the proper functioning of circuits. Among the various types of resistors, spot resistors are particularly significant due to their specific applications and characteristics. This article aims to guide manufacturers in selecting the right spot resistors, emphasizing the importance of understanding their properties, evaluating quality, and considering future trends in the industry.

II. Understanding Spot Resistors

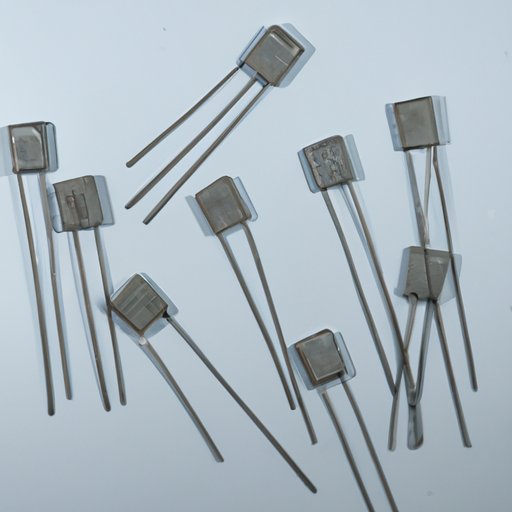

A. What are Spot Resistors?

Spot resistors are specialized resistive components designed for precise applications in electronic circuits. They are typically used in situations where accurate resistance values are critical, such as in voltage dividers, signal conditioning, and biasing applications. Their primary function is to limit current flow, divide voltages, or provide a reference voltage in various electronic devices.

B. Types of Spot Resistors

1. **Fixed Resistors**: These resistors have a constant resistance value and are widely used in applications where the resistance does not need to change. They are available in various resistance values and power ratings, making them versatile for many applications.

2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow for adjustable resistance. They are commonly used in applications such as volume controls, tuning circuits, and calibration settings.

3. **Specialty Resistors**: This category includes a variety of resistors designed for specific applications, such as thermistors (temperature-sensitive resistors), photoresistors (light-sensitive resistors), and precision resistors used in high-accuracy applications.

C. Key Specifications to Consider

When selecting spot resistors, manufacturers must consider several key specifications:

1. **Resistance Value**: The resistance value is the primary specification and should match the requirements of the application. It is essential to choose resistors with the correct resistance to ensure optimal circuit performance.

2. **Tolerance**: Tolerance indicates how much the actual resistance can vary from the specified value. A lower tolerance is preferable for applications requiring high precision.

3. **Power Rating**: This specification indicates the maximum power the resistor can dissipate without overheating. Manufacturers must ensure that the power rating aligns with the expected current and voltage in the application.

4. **Temperature Coefficient**: This parameter describes how the resistance value changes with temperature. A low temperature coefficient is desirable for applications where temperature fluctuations are expected.

III. Factors Influencing the Choice of Spot Resistors

A. Application Requirements

1. **Electrical Characteristics**: Different applications have varying electrical requirements, such as voltage levels, current ratings, and frequency response. Manufacturers must assess these characteristics to select the appropriate resistor type and specifications.

2. **Environmental Conditions**: The operating environment can significantly impact resistor performance. Factors such as humidity, temperature extremes, and exposure to chemicals should be considered when choosing spot resistors.

B. Manufacturing Processes

1. **Material Selection**: The materials used in resistor construction can affect performance, reliability, and cost. Common materials include carbon, metal film, and wire-wound elements. Manufacturers should choose materials that align with their performance and budgetary requirements.

2. **Production Techniques**: The manufacturing process can influence the quality and consistency of resistors. Techniques such as thin-film and thick-film processes offer different advantages in terms of precision and cost.

C. Cost Considerations

1. **Budget Constraints**: Manufacturers must balance performance requirements with budget constraints. While high-quality resistors may come at a premium, investing in reliable components can lead to long-term savings by reducing failure rates and warranty claims.

2. **Long-term Value vs. Initial Cost**: It is essential to consider the total cost of ownership, including potential maintenance and replacement costs, rather than focusing solely on the initial purchase price.

IV. Evaluating Quality and Reliability

A. Importance of Quality in Resistor Manufacturing

Quality is paramount in resistor manufacturing, as poor-quality components can lead to circuit failures, reduced performance, and increased warranty claims. Manufacturers should prioritize quality assurance throughout the production process.

B. Standards and Certifications

1. **ISO Standards**: Compliance with ISO standards ensures that manufacturers adhere to internationally recognized quality management practices. This can enhance credibility and customer trust.

2. **RoHS Compliance**: The Restriction of Hazardous Substances (RoHS) directive limits the use of specific hazardous materials in electronic components. Ensuring compliance with RoHS is essential for manufacturers targeting markets with strict environmental regulations.

C. Testing Methods for Reliability

1. **Endurance Testing**: This testing simulates long-term use to assess how resistors perform under continuous stress. It helps identify potential failure modes and ensures reliability over time.

2. **Temperature Cycling**: This method involves subjecting resistors to extreme temperature variations to evaluate their performance and stability. It is particularly important for applications in harsh environments.

3. **Moisture Resistance**: Testing for moisture resistance ensures that resistors can withstand humid conditions without degrading performance. This is crucial for applications in outdoor or high-humidity environments.

V. Supplier Selection

A. Criteria for Choosing a Supplier

1. **Reputation and Experience**: Manufacturers should seek suppliers with a proven track record in the industry. A reputable supplier is more likely to provide high-quality products and reliable service.

2. **Product Range and Customization Options**: A supplier that offers a wide range of products and customization options can better meet specific application needs.

3. **Customer Support and Service**: Strong customer support is essential for addressing any issues that may arise during the manufacturing process. Manufacturers should choose suppliers that are responsive and willing to collaborate.

B. Building Relationships with Suppliers

1. **Communication and Collaboration**: Open communication fosters a strong partnership between manufacturers and suppliers. Regular discussions about requirements, challenges, and innovations can lead to better outcomes.

2. **Long-term Partnerships**: Establishing long-term relationships with suppliers can lead to improved pricing, priority service, and access to new technologies.

VI. Future Trends in Spot Resistor Manufacturing

A. Technological Advancements

1. **Smart Resistors and IoT Integration**: The rise of the Internet of Things (IoT) is driving demand for smart resistors that can communicate data and adapt to changing conditions. Manufacturers should explore opportunities in this emerging market.

2. **Miniaturization and High-Density Applications**: As electronic devices become smaller and more complex, the demand for miniaturized resistors is increasing. Manufacturers must invest in technologies that enable the production of high-density components.

B. Sustainability and Eco-friendly Practices

1. **Material Sourcing**: Sustainable sourcing of materials is becoming increasingly important. Manufacturers should consider the environmental impact of their material choices and seek eco-friendly alternatives.

2. **Waste Reduction Strategies**: Implementing waste reduction strategies in the manufacturing process can enhance sustainability and reduce costs. This includes optimizing production techniques and recycling materials.

VII. Conclusion

In conclusion, the selection of spot resistors is a critical decision for manufacturers in the electronics industry. By understanding the various types of resistors, evaluating key specifications, and considering factors such as application requirements and supplier relationships, manufacturers can make informed choices that enhance product performance and reliability. As the industry evolves, staying informed about technological advancements and sustainability practices will be essential for long-term success. Manufacturers are encouraged to remain adaptable and proactive in their approach to spot resistor selection, ensuring they meet the demands of a dynamic market.

VIII. References

A. Suggested readings and resources for further exploration:

- "Resistor Technology: A Comprehensive Guide" by John Doe

- "Understanding Resistor Specifications" - Electronics Weekly

B. Industry standards and guidelines for resistor manufacturing:

- ISO 9001: Quality Management Systems

- RoHS Directive Compliance Guidelines

By following the insights and recommendations outlined in this article, spot resistor manufacturers can navigate the complexities of their industry and make choices that lead to successful outcomes.